Liquid Sulphur Black has emerged as a crucial component in various industrial applications, revolutionizing the way manufacturers approach colorant solutions. Its unique properties, which include exceptional colorfastness and versatility, make it an ideal choice for industries ranging from textiles to plastics. As businesses strive for efficiency and sustainability, the significance of Liquid Sulphur Black cannot be overstated; it offers not only superior performance but also aligns with the growing demand for eco-friendly alternatives in manufacturing processes.

In the realm of industrial coloring, Liquid Sulphur Black stands out due to its compatibility with a wide range of substrates, allowing for seamless integration into different production workflows. This adaptability is a critical factor for industries aiming to meet their specific needs while maintaining high standards of quality. Furthermore, the economic advantages of using Liquid Sulphur Black, including reduced processing times and lower waste levels, contribute to its increasing popularity among manufacturers seeking to enhance their operational efficiency.

As we delve deeper into the various applications and benefits of Liquid Sulphur Black, it becomes clear that its role is not merely functional but transformative. Understanding its properties and potential can empower industries to make informed choices that not only improve their product offerings but also foster a more sustainable future in industrial manufacturing.

Liquid Sulphur Black plays a crucial role in various industrial processes, primarily due to its unique properties that enhance product quality and production efficiency. This compound is widely utilized in the manufacturing of dyes, pigments, and other chemical products, providing a reliable option for color consistency and stability. Its solubility and compatibility with various substrates make it an invaluable resource in applications ranging from textiles to plastics, ensuring that industries can achieve the desired aesthetic and functional characteristics in their products.

Moreover, the importance of Liquid Sulphur Black extends to its environmental considerations. As industries increasingly seek sustainable practices, Liquid Sulphur Black offers an eco-friendly solution compared to some traditional alternatives. Its production process can be managed to reduce emissions and waste, making it a favorable choice for companies aiming to comply with environmental regulations while maintaining high-quality output. By integrating Liquid Sulphur Black into their processes, manufacturers can not only improve their operational efficiency but also contribute to a more sustainable industrial landscape.

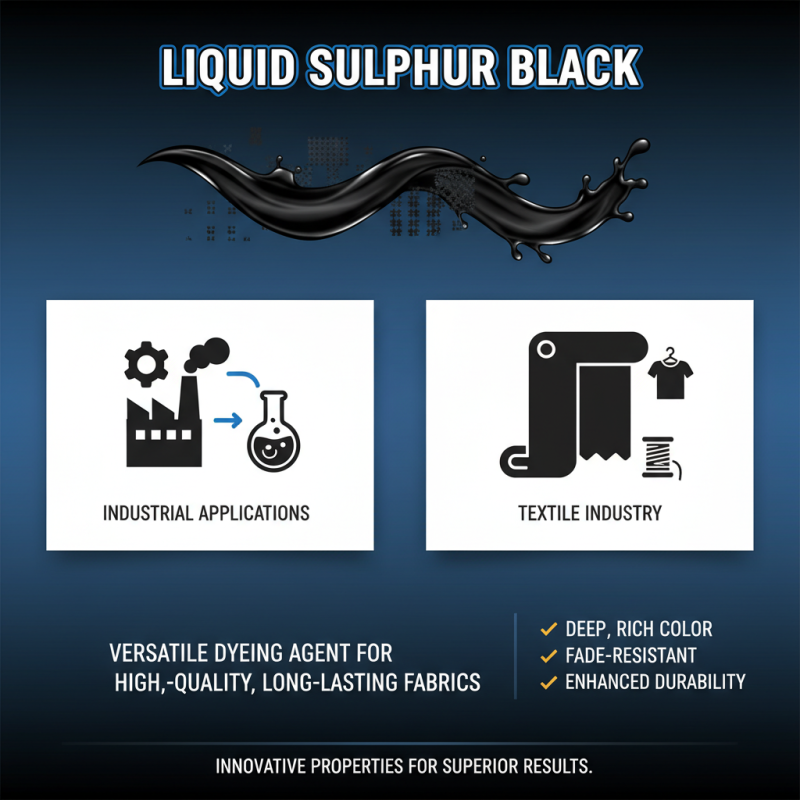

Liquid Sulphur Black is increasingly becoming a vital component in various industrial applications due to its unique properties and versatility. One of the primary industries benefiting from its use is the textile industry, where it serves as an excellent dyeing agent. The deep, rich color that Liquid Sulphur Black provides not only ensures vibrant textile products but also enhances their durability and resistance to fading over time. This makes it a preferred choice for manufacturers looking to produce high-quality and long-lasting fabrics.

Another significant application of Liquid Sulphur Black lies within the rubber industry. It is commonly used as a reinforcing agent in rubber compounding, which enhances the mechanical properties of rubber products. The incorporation of this compound helps improve the wear resistance and elasticity of rubber, making it ideal for manufacturing tires and other rubber components that demand high performance under varying conditions. Furthermore, Liquid Sulphur Black contributes to the creation of anti-aging agents that extend the lifespan of rubber materials in various applications.

Beyond textiles and rubber, Liquid Sulphur Black is also gaining traction in the graphic arts and coatings industries. Its exceptional black pigment quality is utilized in inks and paints, providing a robust solution for achieving deep, uniform coloring that is crucial for print quality and surface finish. Additionally, its stability and compatibility with different mediums make it an essential component in formulations that require high-performance colorants. With these diverse applications, Liquid Sulphur Black is indeed pivotal for industries aiming for efficiency and quality.

Liquid sulphur black is a versatile compound widely used in various industrial applications due to its unique chemical properties. It is primarily known for its high solubility and stability in different environments, which makes it ideal for uses in the textile, rubber, and plastic industries. The production of liquid sulphur black typically involves the reaction of elemental sulphur with carbon black under controlled conditions, resulting in a stable, concentrated product that can enhance the color and durability of various materials.

One of the notable chemical properties of liquid sulphur black is its ability to provide excellent UV protection, which is crucial for products exposed to sunlight. Additionally, its antioxidant properties help extend the lifespan of rubber and plastic products, making them more resilient against degradation. When producing liquid sulphur black, maintaining the right temperature and pressure during the reaction is pivotal to ensure optimal quality and minimize environmental impact.

Tips: When working with liquid sulphur black, always ensure proper ventilation and personal protective equipment to prevent exposure to fumes. Regularly check for consistency in your product’s viscosity and color during production, as these can provide crucial insights into the reaction process and product quality. Proper storage in a cool, dry place can further enhance the longevity and effectiveness of liquid sulphur black.

| Property | Value | Importance in Applications |

|---|---|---|

| Color | Black Liquid | High visibility and corrosion resistance |

| Density | 1.15 g/cm³ | Enhances stability during production |

| Solubility | Soluble in organic solvents | Versatile for various applications |

| Purity | ≥ 98% | Ensures high-quality end products |

| Viscosity | 500 cP | Facilitates easy handling and application |

| pH Level | Neutral (pH 7) | Minimizes potential for chemical reactions |

Liquid Sulphur Black has emerged as a vital component across various industrial applications, particularly in the textile and dye industries. One of the primary advantages of using Liquid Sulphur Black over alternative dyes is its unparalleled color fastness. According to a 2022 industry report, Liquid Sulphur Black demonstrates superior resistance to fading when exposed to light and heat, maintaining vibrant colors even after extensive washing cycles. This property not only enhances the longevity of the products but also reduces the frequency of dye replenishment, leading to significant cost savings for manufacturers.

Additionally, Liquid Sulphur Black boasts environmental benefits that are increasingly becoming essential in today’s eco-conscious market. Unlike many synthetic alternatives, which may require harmful chemical additives and generate toxic by-products, Liquid Sulphur Black is often produced through more sustainable processes. A 2023 environmental impact assessment highlighted that products based on Liquid Sulphur Black can minimize the carbon footprint associated with dyeing processes by up to 30%. This sustainability aspect is vital for companies aiming for greener production methods and compliance with regulations.

Tips: When considering transitioning to Liquid Sulphur Black, evaluate the compatibility with existing machinery and workflows to ease implementation. Additionally, conducting small-scale trials can help measure product performance and color consistency before full-scale adoption. Engaging with suppliers who understand the nuances of Liquid Sulphur Black can also provide valuable insights into optimizing usage in your specific applications.

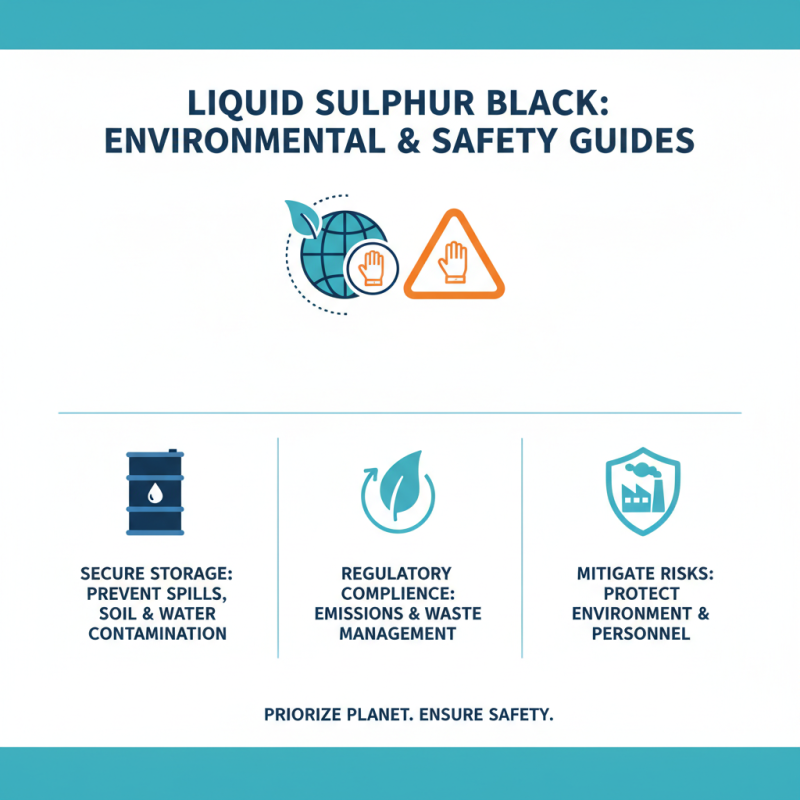

When handling Liquid Sulphur Black, it is imperative to prioritize environmental considerations and safety protocols to mitigate potential risks. This compound, while beneficial for various industrial applications, can pose environmental hazards if not managed correctly. It is critical to store Liquid Sulphur Black in designated containment areas to prevent spills, which can lead to contamination of soil and water sources. Furthermore, facilities should ensure that they comply with local regulations regarding emissions and waste management to minimize their ecological footprint.

Safety is another crucial aspect of managing Liquid Sulphur Black. Personnel involved in its handling must be adequately trained in safe operating procedures and the use of personal protective equipment (PPE). This includes gloves, goggles, and respirators to protect against inhalation and skin contact. Implementing strict protocols for handling spills and exposure incidents can further safeguard workers and the environment. Regular safety audits and drills can enhance readiness and ensure that all employees understand the potential risks associated with Liquid Sulphur Black, fostering a culture of safety in the workplace.