In the textile and dyeing industry, the significance of Sulphur Black Liquid is undeniable. Dr. Emily Johnson, a leading expert in dye chemistry, once stated, "Understanding Sulphur Black Liquid is crucial for achieving deep, rich colors in fabrics." This complex solution offers various benefits but requires careful handling and application.

Sulphur Black Liquid is a popular choice for dyeing textiles, especially cotton and wool. Its unique properties make it efficient for creating dark shades. However, many users struggle with its application. Factors like temperature, time, and dyeing methods can significantly impact the final results. It’s essential to experiment and refine your technique for optimal use.

Furthermore, the industry often overlooks safety measures. Improper handling can lead to unwanted outcomes. Users must remain aware of potential risks during application. With the right knowledge, Sulphur Black Liquid can produce exceptional results. Still, it demands a level of respect and understanding from those in the industry.

Sulphur Black Liquid is a complex chemical substance used primarily in dyeing. Its deep, rich color makes it popular for textiles. The liquid is derived from various sources, including natural and synthetic materials. The main component is elemental sulfur, which combines with other chemicals to create this unique dye.

In terms of composition, Sulphur Black Liquid contains sulfur compounds, water, and additional agents for stability. The balance of these ingredients is crucial. An improper mix can lead to inconsistent coloring. Some users report challenges when achieving the desired shade. It's essential to test small samples before large-scale application. This approach helps to identify any issues early on. Adjusting water temperature or pH levels may also be necessary for optimal results.

Using Sulphur Black Liquid effectively requires attention to detail. Maintaining the right temperature during dyeing impacts the final shade. Additionally, ensuring that the materials are clean can enhance color uptake. Many users learn through trial and error, which can be frustrating. The liquid may behave differently depending on the fabric type. Experimentation and careful observation can lead to improved outcomes over time.

Sulphur Black Liquid is a versatile dye that finds applications across various industries. In textiles, it provides a rich black color to fabrics, enhancing their aesthetic appeal. This dye is particularly effective on cotton and wool. Its ability to achieve deep shades makes it a favorite among manufacturers. However, achieving uniform application can be challenging. Many producers struggle with consistency, which can lead to visible streaks or fading.

In the paper industry, Sulphur Black Liquid is used for coloring pulp. It helps achieve desirable shades without sacrificing the strength of the paper. However, balancing color and quality requires precise control over the application process. Any miscalculation may result in unwanted hues or texture issues. These inconsistencies often prompt revisiting the mixing technique.

The leather sector also utilizes this dye for providing a deep finish. Its application not only amps up the product's appeal but also provides certain protection against wear. Yet, excessive use can lead to insufficient flexibility, making the leather stiff. Craftsmanship and proper usage can make a significant difference here. It's essential for artisans to continually refine their methods to avoid such pitfalls.

Using Sulphur Black Liquid can be quite effective if done right. To start, prepare the workspace. Ensure it's well-ventilated and free of clutter. Gather your materials: gloves, brushes, and containers. This product can stain skin and surfaces.

Mix the Sulphur Black Liquid with water according to the instructions. Use a clean container for this. The goal is to achieve the right consistency. A thicker mix can yield a deeper color, while a thinner mix might not give you the desired shade.

Tips: Always test on a small fabric piece first. This helps in understanding how the fabric reacts. Also, work in small sections to maintain even coverage. After applying, allow ample time for the dye to set. Rushing through this step may result in uneven coloration.

Remember, not every application will be perfect. You might notice splotches or uneven dyeing. Reflect on what went wrong. Is the mix consistent? Did you apply it evenly? Learning from these mistakes can lead to better results in future projects.

When dealing with Sulphur Black Liquid, safety must come first. This chemical can cause skin irritation and respiratory issues. According to the Occupational Safety and Health Administration (OSHA), exposure can lead to serious health risks. Personal protective equipment (PPE) is essential. Wearing gloves, masks, and goggles is a must. Workers should also ensure good ventilation in their workspace.

Handling spills is another critical concern. An effective spill response plan should be in place. As per the Environmental Protection Agency (EPA), a quick clean-up prevents hazardous exposure. The liquid's fumes pose risks when inhaled. Ensuring that all containers are sealed tightly helps minimize vapor dispersion. Additionally, proper training on emergency procedures is vital.

Even with safety measures, mistakes can happen. Inadequate training may lead to accidents. A common oversight is neglecting to check equipment regularly for damage. Monitoring chemical usage can also prevent excess exposure. Regular safety audits help identify potential risks. The goal is to create a safer environment for everyone involved.

This bar chart illustrates the percentage usage of Sulphur Black Liquid across various industries, indicating that the textile dyeing industry is the most frequent user, followed by the paper industry, cosmetics, and paints & coatings.

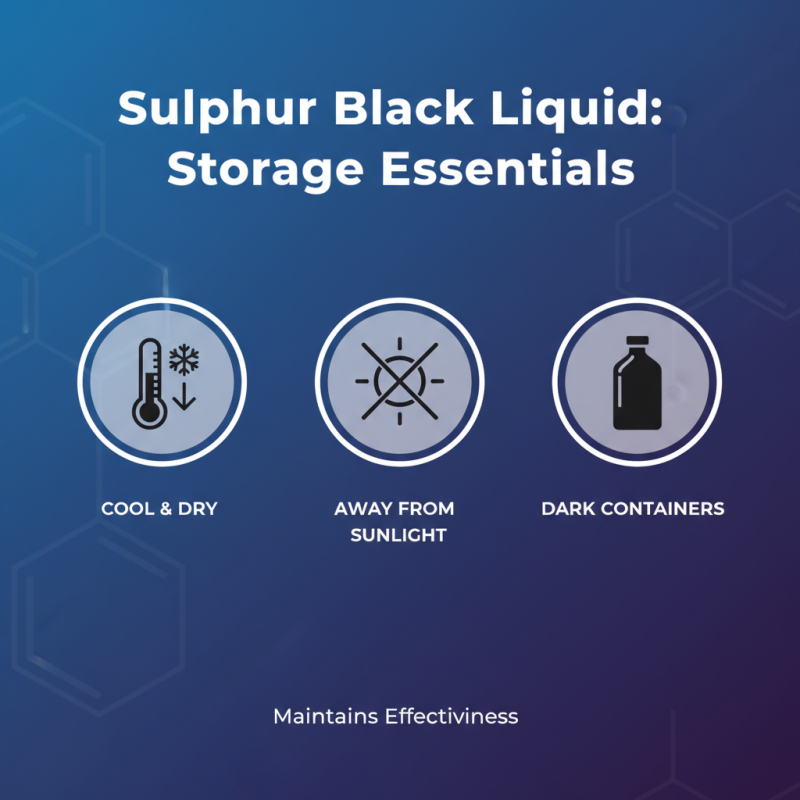

Sulphur black liquid is a versatile dye used in various applications. Proper storage of this liquid is essential to maintain its effectiveness. It should be kept in a cool, dry place, away from sunlight. High temperatures can degrade its quality. Use dark containers for storage to minimize light exposure.

Ensure that the containers are airtight. Open containers can lead to contamination and evaporation. It’s important to check for any signs of precipitation or separation before use. If the liquid looks different than expected, rethink your approach.

Always label the containers with the date of storage. This helps track the liquid's shelf life. Generally, store it for no more than a year. When in doubt about its usability, test a small sample. This precaution can save time and resources in the long run.