In the world of textile coloring, "Black Reactive Dye" stands out for its effectiveness and versatility. According to Dr. Emily Carter, a renowned expert in dye chemistry, “The key to successful fabric coloring lies in understanding the properties of Black Reactive Dye.” This statement encapsulates the importance of mastering dye techniques.

Understanding how to use Black Reactive Dye requires attention to detail. The dye works best on cellulose fibers. However, achieving optimal results can be challenging. Various factors influence the dyeing process, such as temperature and pH levels. Missteps can lead to uneven colors or fading. It’s crucial to experiment and find the perfect balance.

For artists and manufacturers, Black Reactive Dye provides vibrant, long-lasting colors. But improper usage can lead to dissatisfaction. It’s essential to carefully measure and test before the final application. Achieving the desired shade may take several attempts. Embracing this trial-and-error method ultimately leads to success in coloring fabrics with Black Reactive Dye.

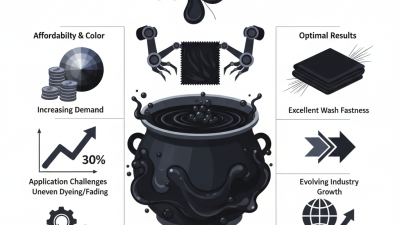

Black reactive dye has gained attention for its versatility and effectiveness in fabric coloring. This dye type is known for its strong bonding with fibers, resulting in vibrant and long-lasting colors. Unlike some traditional dyes, it reacts chemically with fabrics, which allows for deeper penetration. Industry reports reveal that the global textile dye market is projected to reach $3.2 billion by 2025. This growth indicates an increasing reliance on reactive dyes like black for high-quality fabric finishes.

Using black reactive dye comes with several benefits. It enhances color fastness to washing and sunlight exposure. Fabrics dyed with this method can endure up to 50 washes, retaining color integrity and appeal. However, achieving perfect results requires careful attention. The dyeing process can be sensitive to temperature and pH levels. A slight deviation could lead to uneven coloration or fading. Users often overlook these factors. It’s crucial to experiment with samples before executing large batches. The approach can lead to some unanticipated outcomes.

Industry data suggests that 85% of textile manufacturers report variations in the dyeing process. This highlights the importance of testing and adjusting techniques. Black reactive dye’s potency can sometimes result in excessive color intensity, requiring dilution. Understanding the balance is key. While it offers a range of benefits, it also presents challenges that require awareness and adaptation. Observing these nuances can make a significant difference in final results.

This chart illustrates the color intensity achieved on various fabric types using black reactive dye. The results show that silk has the highest color intensity, followed closely by cotton. Polyester and wool show moderate intensity, while nylon also performs well.

When preparing your fabric for dyeing, proper steps are essential. Start by washing the fabric. This removes any residues or finishes. Residual chemicals can prevent dye absorption. After washing, dry the fabric thoroughly. A damp fabric may lead to uneven coloring.

Tips: Use a mild detergent for best results. It’s crucial to rinse well. Any soap left may affect the dye.

Next, you should consider the fabric type. Not all fabrics absorb dye equally. Natural fibers like cotton and linen are best. Synthetic materials may resist color. If you’re unsure, test a small swatch first. It’s a good way to see the final result.

Tips: Always conduct a patch test. This practice saves you from making mistakes later. Document your results for future reference.

Lastly, keep in mind that dyeing is often an imperfect science. Factors like water temperature influence outcomes. Sometimes, variations in fabric texture result in unexpected shades. Embrace these imperfections. They add character to your projects.

Mixing black reactive dye requires careful attention to proportions. The typical dye-to-water ratio is around 1:20 for optimal saturation. However, this can vary based on fabric type. Cotton fibers often absorb dyes more readily than synthetics. This means you might need to adjust your ratio for different fabrics. For instance, using a 1:15 ratio for canvas can yield deeper hues.

The method of mixing can also affect the outcome. Start by dissolving the dye in hot water. Stir it thoroughly until fully dissolved. An industry report highlights that inconsistent mixing can lead to patchiness in color. Once mixed, adding salt can improve the dye's fixation. According to a study, using 10% salt can enhance color uptake significantly. This step is crucial, especially if aiming for a rich, even black.

Test your mixture on a fabric swatch first. This can prevent unexpected results on larger projects. Many users overlook this step, leading to dissatisfaction with the final product. Keep track of your mixes and adjustments. This practice can help refine your technique over time. Remember, dyeing is as much an art as it is a science. Experimentation is often needed to achieve the desired results.

When dyeing fabric with black reactive dye, uniformity is key. Start by preparing your dye bath correctly. Use warm water to dissolve the dye thoroughly. The temperature should be around 130°F. Stir it gently to avoid clumping. Make sure your fabric is clean. Any residue can cause uneven coloring. Pre-soaking the fabric in soda ash can enhance the dye’s effectiveness.

Application techniques matter a lot. Submerging the fabric completely ensures even distribution of color. Stir continuously for about 20 minutes. This action helps to prevent patchiness. If ink spots appear, it might be due to fabric texture. Always test a small section first. You might face challenges like inconsistent dye uptake. Adjust your soaking time accordingly.

At times, the final result may not be what you expected. Variations can occur based on fabric content. Lighter and darker areas might arise, which may not look ideal. Embrace these unique imperfections. Each piece tells a story through its color. Reflect on the process and learn from any mistakes. This will improve your dyeing projects.

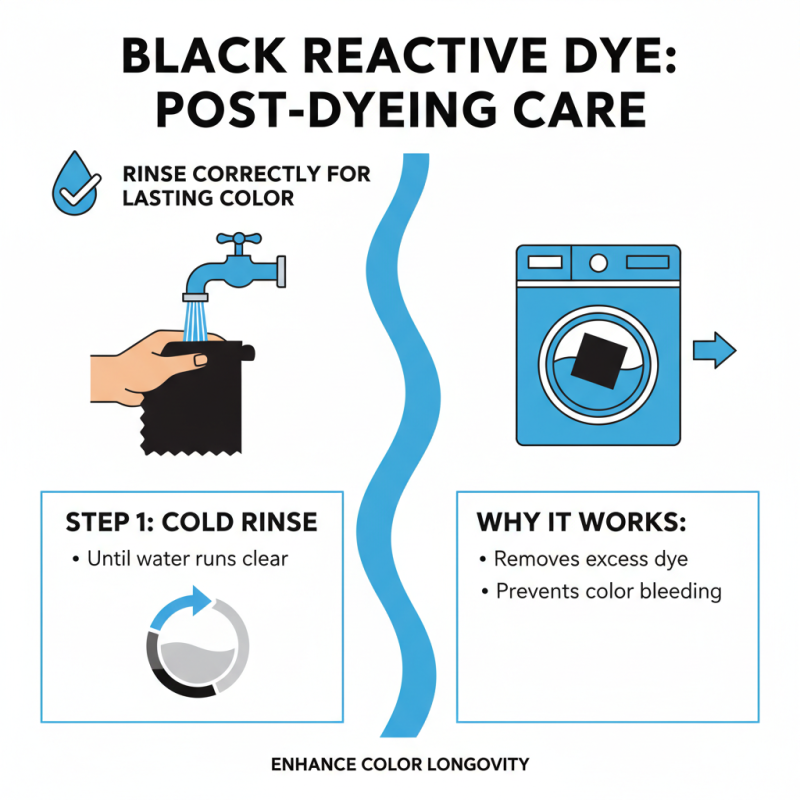

Post-dyeing care is crucial when using black reactive dye. Rinsing the fabric correctly can enhance the color's longevity. After dyeing, rinse the fabric in cold water until the water runs clear. This step removes excess dye, preventing color bleeding in future washes.

Washing the dyed fabric requires more attention. Use a gentle cycle with cold water. Avoid harsh detergents. They can fade the color quickly. Instead, consider using a mild soap. Be careful with mixed loads; the dye might transfer to lighter fabrics.

Tip: To set the color, use a vinegar rinse after washing. It helps lock in the dye. After rinsing, hang the fabric to air dry. The sun can help brighten the color, but too much exposure may fade it. Be mindful of the drying location—direct sunlight can be damaging.

Dyeing can be unpredictable. Some fabrics absorb color better than others. Always test a small swatch before dyeing a larger piece. This trial can save time and materials in the long run. Keep experimenting to find the best methods for your unique fabrics.