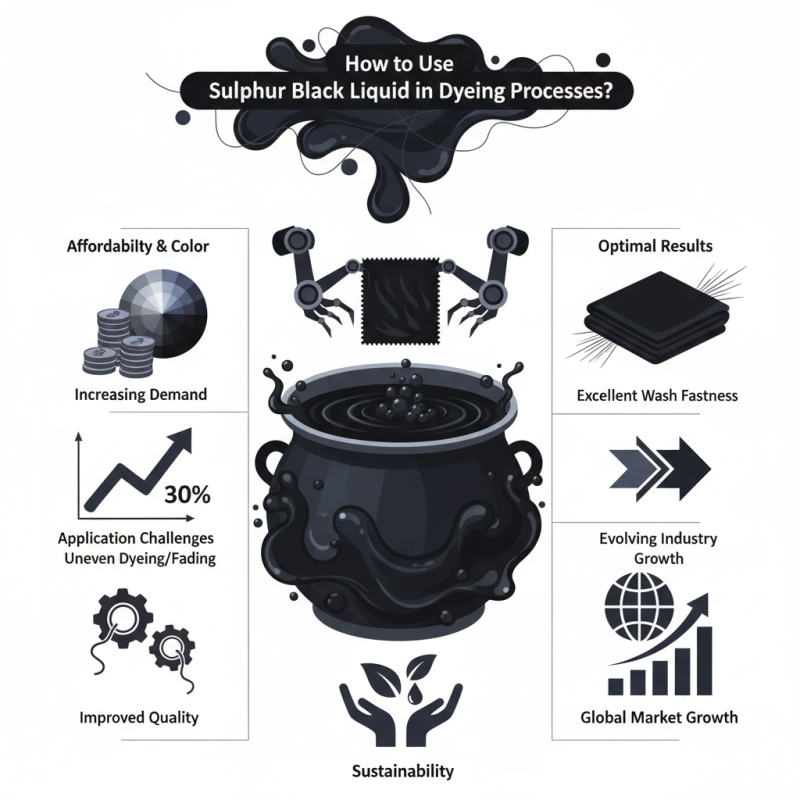

The use of Sulphur Black Liquid in dyeing processes has gained traction in the textile industry. Recent industry reports indicate that demand for sulfur-based dyes is increasing, due to their affordability and vibrant colors. Sulphur Black Liquid is particularly valued for its deep, rich hue and excellent wash fastness. However, proper usage is crucial for optimal results.

Despite its advantages, difficulties in application can arise. For instance, issues like uneven dyeing or color fading may occur if the Sulphur Black Liquid is not managed correctly. Some studies suggest that about 30% of textile manufacturers face challenges in achieving consistent results. This raises important questions about dyeing techniques and the need for better training in handling these materials.

As the industry evolves, the importance of effective dyeing methods becomes more apparent. The global market for sulfur dyes, including Sulphur Black Liquid, is projected to reach significant growth. Attention to these processes can enhance product quality and sustainability. It is essential for manufacturers to reflect on their practices and continuously improve in order to meet consumer demands.

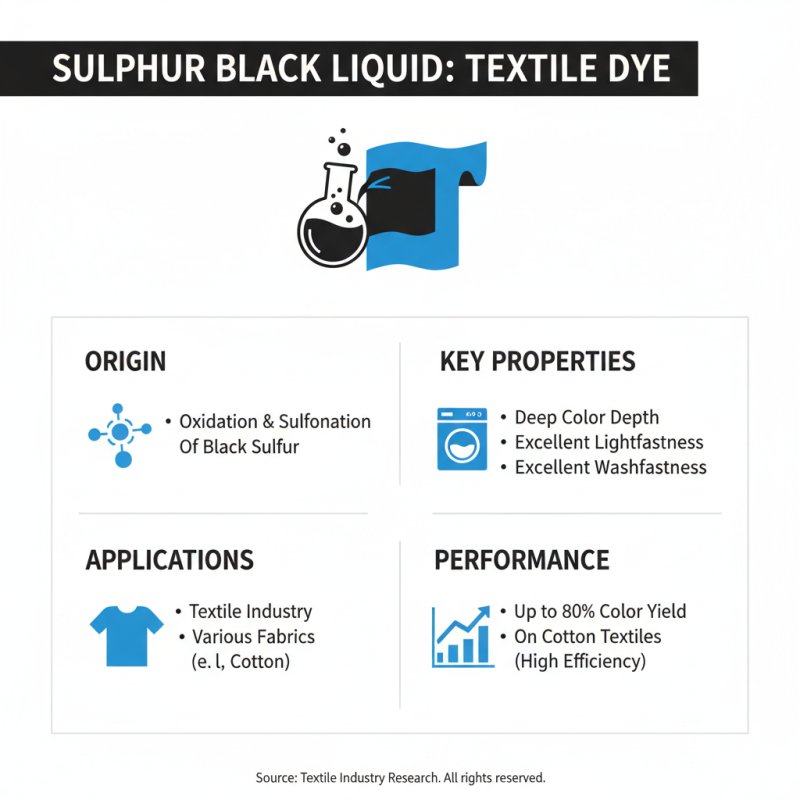

Sulphur Black Liquid is a well-known dye used in textile applications. It is derived from the oxidation and sulfonation of black sulfur and is recognized for its depth of color. This dye exhibits excellent lightfastness and washfastness properties, making it suitable for various fabrics. Studies indicate that sulphur dyes, including Sulphur Black, can achieve a color yield of up to 80% on cotton textiles, which is a significant advantage in the dyeing industry.

The application process involves a few specific steps. Initially, the fabric must be pre-treated to enhance the uptake of the dye. This involves using an alkaline solution, which prepares the fibers for better absorption. During the dyeing process, the temperature and pH levels need to be carefully monitored. Deviations in these parameters can lead to suboptimal results, such as uneven color distribution. Observations show that maintaining a temperature between 70°C to 90°C yields the best outcomes for consistent dyeing.

Despite its benefits, using Sulphur Black Liquid is not without challenges. The dyeing process can produce unwanted residues, which may lead to environmental concerns. Proper wastewater treatment is essential to mitigate these issues. Reflections on this task reveal a need for more sustainable practices in dyeing. Industries are encouraged to explore biodegradable alternatives or improve recycling methods for wastewater. These efforts could lead to a more environmentally responsible application of Sulphur Black Liquid.

When dyeing with sulphur black liquid, the right equipment is essential. You will need a large dyeing pot. Stainless steel or enamel works well. Make sure it can handle heat. Safety goggles and gloves are also crucial. These protect you from the dye’s intensity. Always have a scale to measure the dye accurately. Precision is key for even coloring.

Collect materials such as water, salt, and a reducing agent. The water should be warm to help the dye dissolve. Salt helps fix the color to the fabric. The reducing agent, often a simple chemical, enhances the dyeing process. You might want to use natural fibers. Cotton and wool respond best to sulphur black. Synthetic fabrics can be tricky.

Remember that this process can be messy. Stains might occur, and color can vary. Experimenting can lead to unforeseen results. Take notes on your ratios and methods. This will help you refine your technique. Each attempt is a learning opportunity. Keep your space organized to reduce chaos. Unpredictable outcomes can lead to great discoveries in your dyeing journey.

Preparing a dye bath with Sulphur Black Liquid requires careful attention to detail. Start by gathering all necessary materials. You will need the dye, water, and a suitable container. Measure the water volume accurately. A typical ratio is 1 part dye to 10 parts water. Professional reports suggest that maintaining this ratio can ensure consistent results, with over 90% color fastness in many applications.

Heat the water to around 60°C before adding the Sulphur Black Liquid. This temperature helps dissolve the dye effectively. Stir the mixture gently to avoid clumping. Many dyers report that undissolved dye can lead to uneven results on fabric. Allow the dye to sit for about 30 minutes. This waiting period is crucial for a uniform color.

Test the bath with a small fabric swatch. It’s essential to check the color before full immersion. Sometimes, the results may not meet expectations. Adjust the dye concentration if necessary. Observations from experienced dyers emphasize the importance of this step. They note that slight variations in temperature or dye concentration can significantly impact the final outcome. Always be prepared to adapt as needed.

When using sulphur black liquid, precision is key. This dye offers deep, rich shades when applied correctly. To achieve your desired color intensity, consider your fabric type.

Natural fibers absorb dyes better than synthetics. Ensure fabrics are pre-washed to remove any coatings. A clean surface allows for even dye uptake.

To achieve vibrant results, monitor dyeing time closely. Long exposure can lead to overly dark shades. On the flip side, too brief a soak may yield pale colors.

Test small fabric samples first. This experimentation helps find the right balance.

Tips: Maintain consistent stirring in the dye bath. This prevents uneven coloration. After dyeing, rinse thoroughly to remove excess dye. Keep in mind that dye intensity varies with concentration.

Sometimes, darker shades can look dull. Adjusting water temperatures can also shift results. If colors are not as vivid as hoped, reflect on your process and try again.

Post-dyeing treatment is crucial for sulphur black dyed fabrics. Proper care enhances the color's longevity and overall appearance. According to a study by The Textile Institute, about 30% of color fading stems from insufficient post-treatment processes. Fabrics need to be thoroughly washed after dyeing to remove excess dye. This washing can prevent dye transfer during subsequent washes.

After washing, it's essential to use a fixative. A good fixative can prevent color bleeding and fading, which are common issues with sulphur dyed textiles. Reports indicate that using a fixative can improve color fastness by up to 50%. However, not all fixatives work equally well. Testing on a sample is recommended to ensure compatibility.

When caring for sulphur black dyed fabrics, avoid harsh detergents. Soaking fabric in cold water may help maintain color vibrancy. Drying in direct sunlight can lead to fading, so it’s best to air dry in the shade. Note that some fabrics may still exhibit slight discoloration over time despite best efforts. Keeping these factors in mind ensures durability and satisfaction with these dyed textiles.