0102030405

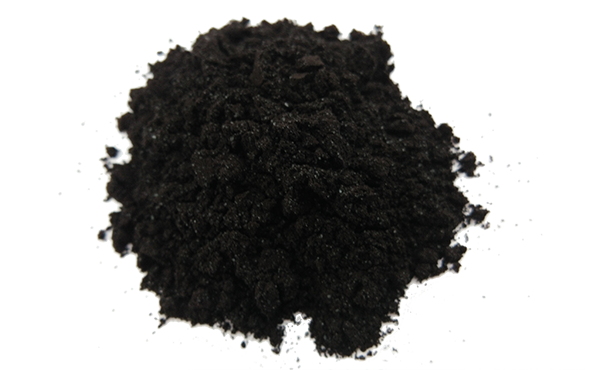

Sulphur Blue CV 120% For Blue-Gray Powder

Product Specification

Name |

Sulphur Blue CV |

Other Names |

Sulphur Blue 15 |

CAS No. |

1327-69-1 |

STRENGTH |

100% 120% |

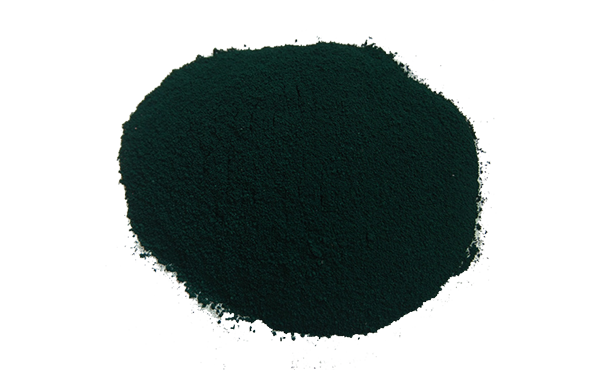

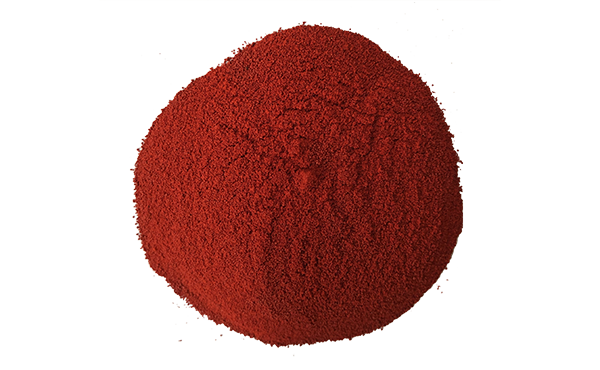

APPEARANCE |

Blue-Gray Powder |

APPLICATION |

Used for dyeing Cotton, Jeans ,Denim and so on. |

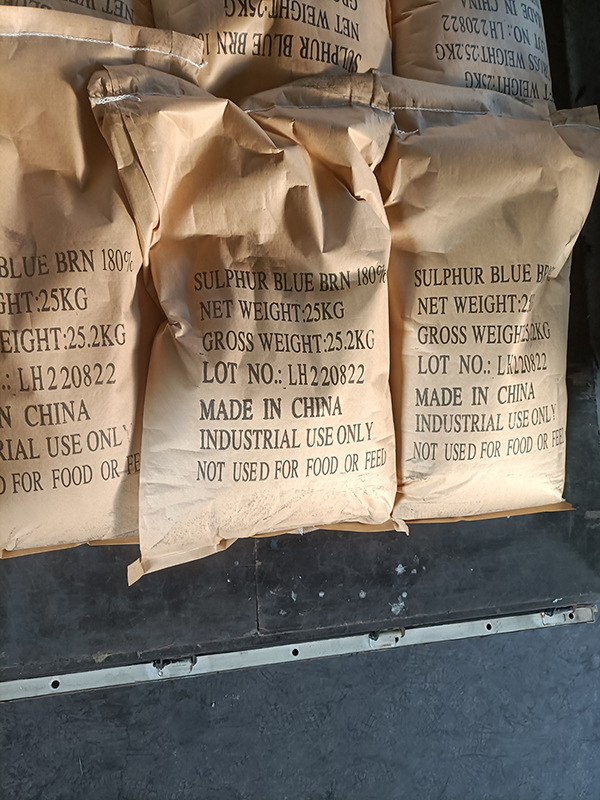

PACKING |

25KGS PP Bag/Kraft Bag/Carton Box/Iron Drum |

Product Description

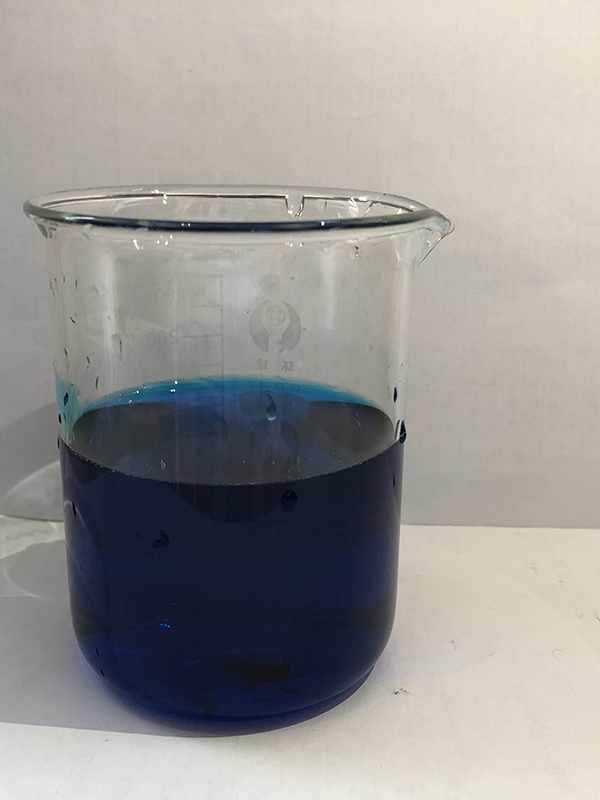

The Sulphur Blue CV Slightly soluble in water. Olive color in sodium sulfide solution. It is dark blue in concentrated sulfuric acid and produces dark blue precipitate after dilution. The alkaline insurance powder is dark yellow in the solution, and the normal color is restored after oxidation.

Product character

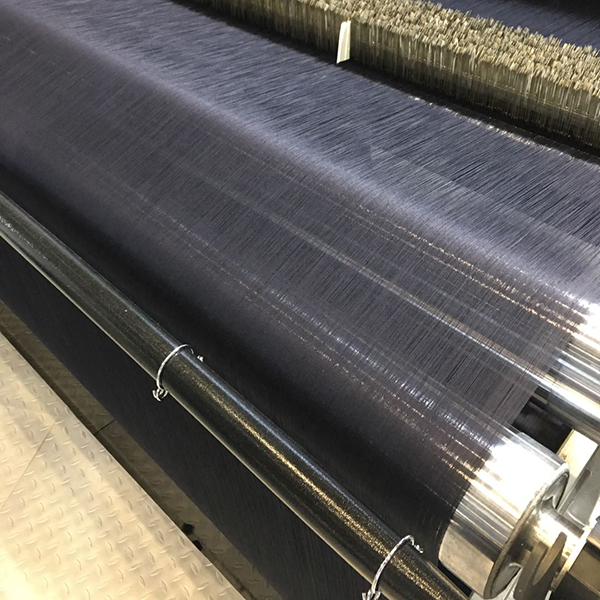

A. Sulphur blue CV is suitable for dyeing Cotton, Jeans ,Denim and so on.

B. Especially suitable for dyeing cotton, linen, viscose, vinylon and other thick fabrics dark color spectrum, simple process, easy to use, need to add antioxidants when dyeing light colors, no antioxidants when dyeing dark colors, stable color, bright color, high wetness fastness, small color difference, can improve the qualified rate of finished products.

C.The dye has a high dyeing rate on the fiber and good uniformity; However, the rate of oxidation is slower. After dyeing, the water should be washed sufficiently, so that the sulfide alkali remaining on the cloth surface is removed, the dye oxidation is accelerated, and the cloth surface is uniform. The temperature is below 70 C, the color is dark and vivid, the temperature is too high, the color light turns gray, and the uniformity is poor.

D.When used for cotton dyeing, baking soda can be added to the rolling and dyeing solution, the amount is 10%~ 15% of the sulfide alkali, should not be too much, otherwise the dyeing is not transparent, resulting in white core.

E.When dyeing vinylon, the color is lighter than that of dyed cotton, the color light is also dark, and the uniformity is also poor.

F.It is often used to spell blue and green and other colors. When dyeing, you need to pay attention to the dyeing temperature of the dye, otherwise it is easy to produce color difference.

H. The use of hydrogen peroxide or sodium perborate is better, the color is bright, there is blue light, but the soap fastness is reduced.

Note:

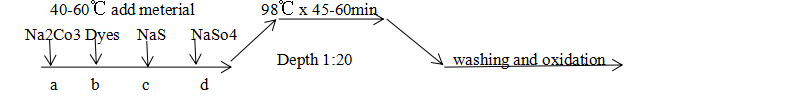

①a--Na2Co(g/L);b--x%(0.w.f);c--Na2S:dyes=2~1:1;d--Na2So4(5-10g/L);

②The dyes is applied in advance to the commendation(wetting);

③After add dyes,usually heat at 1℃/min,heating to 98-100℃,and then keep the temperature 45-60 min for dyeing.

④After dyeing,washing→ Oxidation of air or oxidants,40℃ and keeping 20min →washing→drying

Usage: It is mainly used for dyeing cotton and other natural fibers, and is suitable for dyeing fabrics, yarns, and fibers.

The product must be stored in shade, dry & well-ventilated warehouse. Avoid to be contacted with oxidizing chemicals and combustible organic substances. Keep it away from direct sunlight, heat, sparks and open flames. Carefully handle the product and avoid damaging the package.

25KGS Kraft Bag/Fibre Drum/Carton Box/Iron Drum